Documentation

Descrição

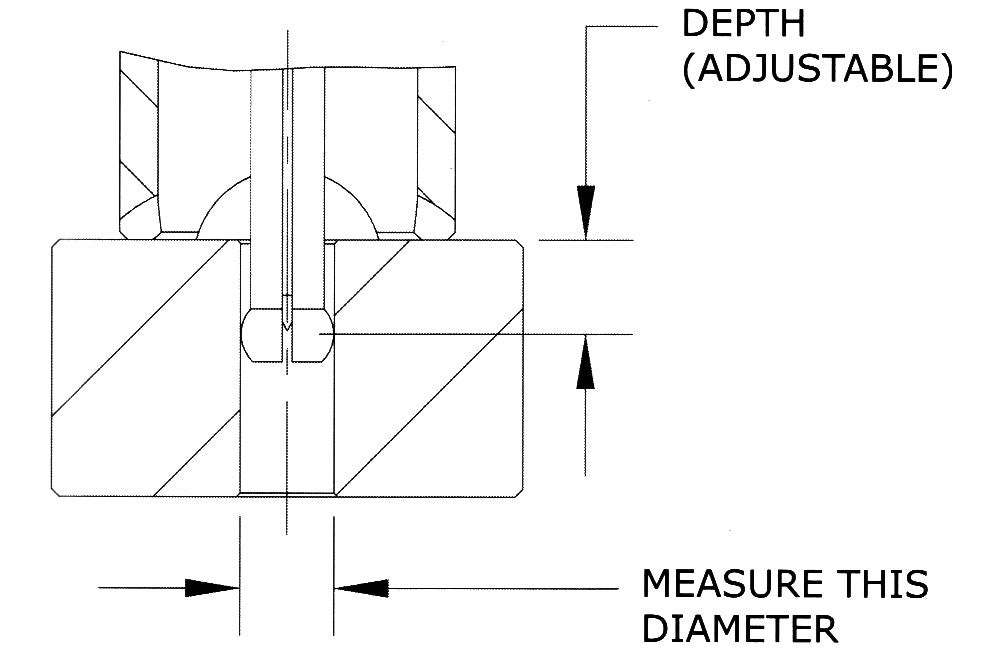

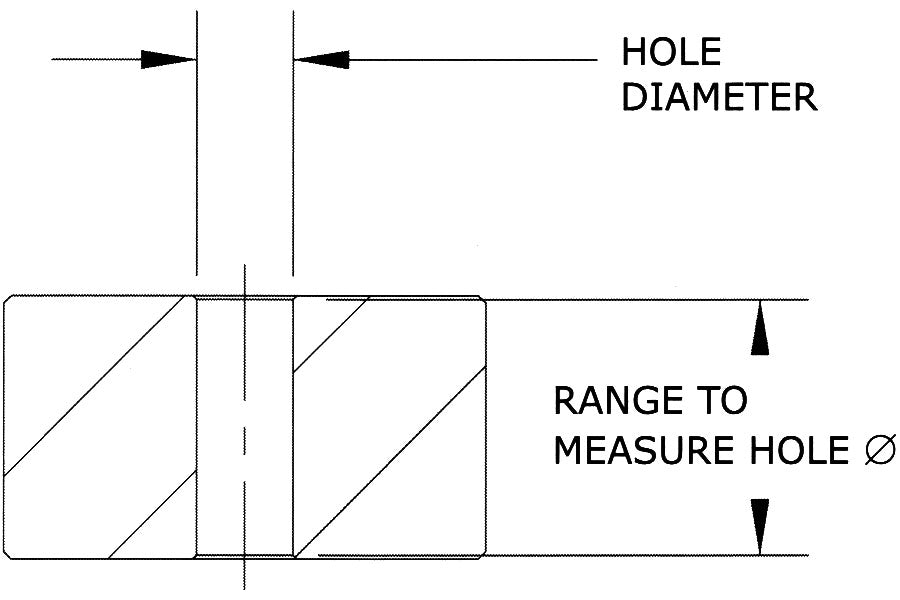

A high precision digital gage for quick and accurate measurements of the hole diameter at different depths. This gage has the capability to lock in the position of the probe through a 1.25-inch depth range. The last four digits of the gage part number represent the probe diameter. The measuring range of the probe is approximately ±.020 inches around the nominal diameter stated. The gage body has machined positioning lines spaced equally at .0625 inches intervals for probe depth adjustment. An outer locking base ensures that the operator can check the hole ID at the same depth that the gage has been preset at.

Features:

- Measuring accuracy .0001 inch (.0025mm)

- Direct contact inside the hole at any depth.

- Direct reading of the bore diameter.

- Different base configurations are available for curved surfaces.

- Accurate, repeatable, and reproducible.

- SPC ready via data port cable.

- Ease of use with minimal training.

- Eliminate costly rework.

- Gage and set block calibrated to NIST traceable standards.

- Unique serial numbers on gages, set blocks, and indicators.

- The components of our gages are made of heat-treated wear-resistant tool steels and micro-finished to ensure accurate and trouble-free operation.

Digital Indicators Features:

- LCD display with rotating bezel.

- Inch/ mm mode toggle capable.

- SPC data output ready via the data port.

- Upper and lower tolerance capable.

- User-selectable resolution (Mahr-Federal).

- Auto power off after 15 minutes of inactivity (Mahr-Federal).

- Lockout of setup preset (access key- Mahr-Federal, computer -Mitutoyo)

- Choice of indicators: Mahr-Federal, Mitutoyo, or Sylvac (please advise of your preference).

Trulok® gages are built to your exact specifications. Please supply us with the following data needed for the calibration set block that will accompany the gage:

- Hole diameter with tolerances:

- Ranges of hole diameters to measure:

- Surface curvature: