Documentation

Descripción

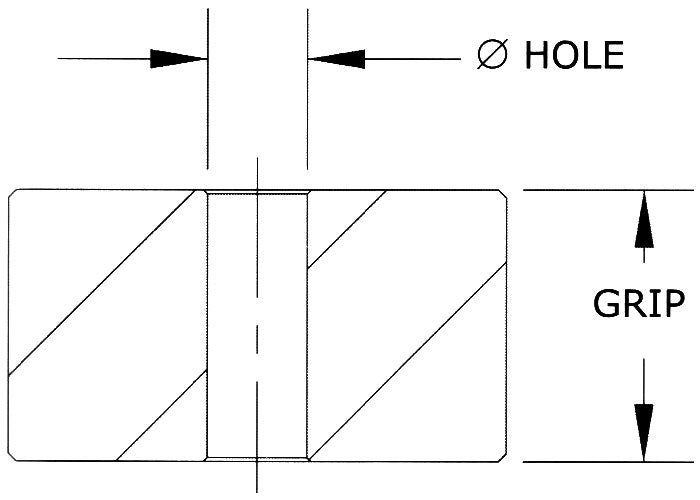

This is a high precision digital gage for quick and accurate measurement of the structure thickness expressed in grip values. This gage was developed to replace the existing scale or mechanical type grip gages in use today. The digital indicator use allows the gage to express the readings in grip numbers as expressed in the fastener standards and used by the fastener manufacturing companies. The precision and accuracy of this digital type gage is also much higher than the existing gages in use now. The fixed range design has the same precision and accuracy as the modular grip gage but it has a fixed grip range Oto 16 grip (0.000 to 1.000 inch) or Oto 32 grip (0.000 to 2.000 inch). Expressing the measurements in grip values eliminates any conversion errors (inch to mm, for example) and gives the operator the ability to select the proper fastener for the given thickness of the structure.

Features:

- Measuring accuracy .0001 inch (.0025mm)

- Direct reading, no calculations or charts necessary.

- Accurate, repeatable, and reproducible.

- SPC ready via data port cable.

- Ease of use with minimal training.

- Eliminate costly rework.

- Gage and set block calibrated to NIST traceable standards.

- Unique serial numbers on gages, set blocks, and indicators.

- The components of our gages are made of heat-treated wear-resistant tool steels and micro-finished to ensure accurate and trouble-free operation.

Digital Indicators Features:

- LCD display with rotating bezel.

- Inch/ mm mode toggle capable.

- SPC data output ready via the data port.

- Upper and lower tolerance capable.

- User-selectable resolution (Mahr-Federal).

- Auto power off after 15 minutes of inactivity (Mahr-Federal).

- Lockout of setup preset (access key- Mahr-Federal, computer -Mitutoyo)

- Choice of indicators: Mahr-Federal, Mitutoyo, or Sylvac (please advise of your preference).

TRULOK® gages are built to your exact specifications. The calibration set block is determined by the required grip range. Please supply us with the following data:

- "G" Fastener grip standard:

- "GR" The grip range to measure:

- Minimum hole diameter through:

- Fastener part number and/or specification:

- Surface curvature: