Documentation

Description

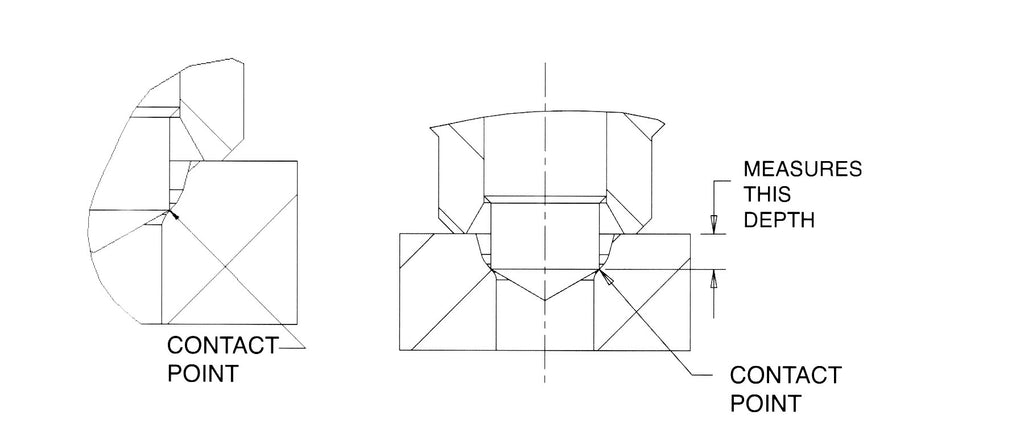

A high precision digital gage for quick and accurate measurement of the double countersink depth at a specific contact diameter. The SR907 depth gage has a fixed diameter probe with a chamfered end that contacts the inside wall of the countersink at a preset depth (see detail). This gage can be used to set cages or micro-stops. The use of this gage will reduce rework by checking the countersink depth before installing the fastener.

Features:

- Measuring accuracy .0001 inch (.0025mm)

- Direct contact inside the countersink walls.

- Direct reading, no calculations or charts necessary.

- Large base configurations are available for curved surfaces.

- Accurate, repeatable, and reproducible.

- SPC ready via data port cable.

- Ease of use with minimal training.

- Eliminate costly rework.

- Gage and set block calibrated to NIST traceable standards.

- Unique serial numbers on gages, set blocks, and indicators.

- The components of our gages are made of heat-treated wear-resistant tool steels and micro-finished to ensure accurate and trouble-free operation.

Digital Indicators Features:

- LCD display with rotating bezel.

- Inch/ mm mode toggle capable.

- SPC data output ready via the data port.

- Upper and lower tolerance capable.

- User-selectable resolution (Mahr-Federal).

- Auto power off after 15 minutes of inactivity (Mahr-Federal).

- Lockout of setup preset (access key- Mahr-Federal, computer -Mitutoyo)

- Choice of indicators: Mahr-Federal, Mitutoyo, or Sylvac (please advise of your preference).

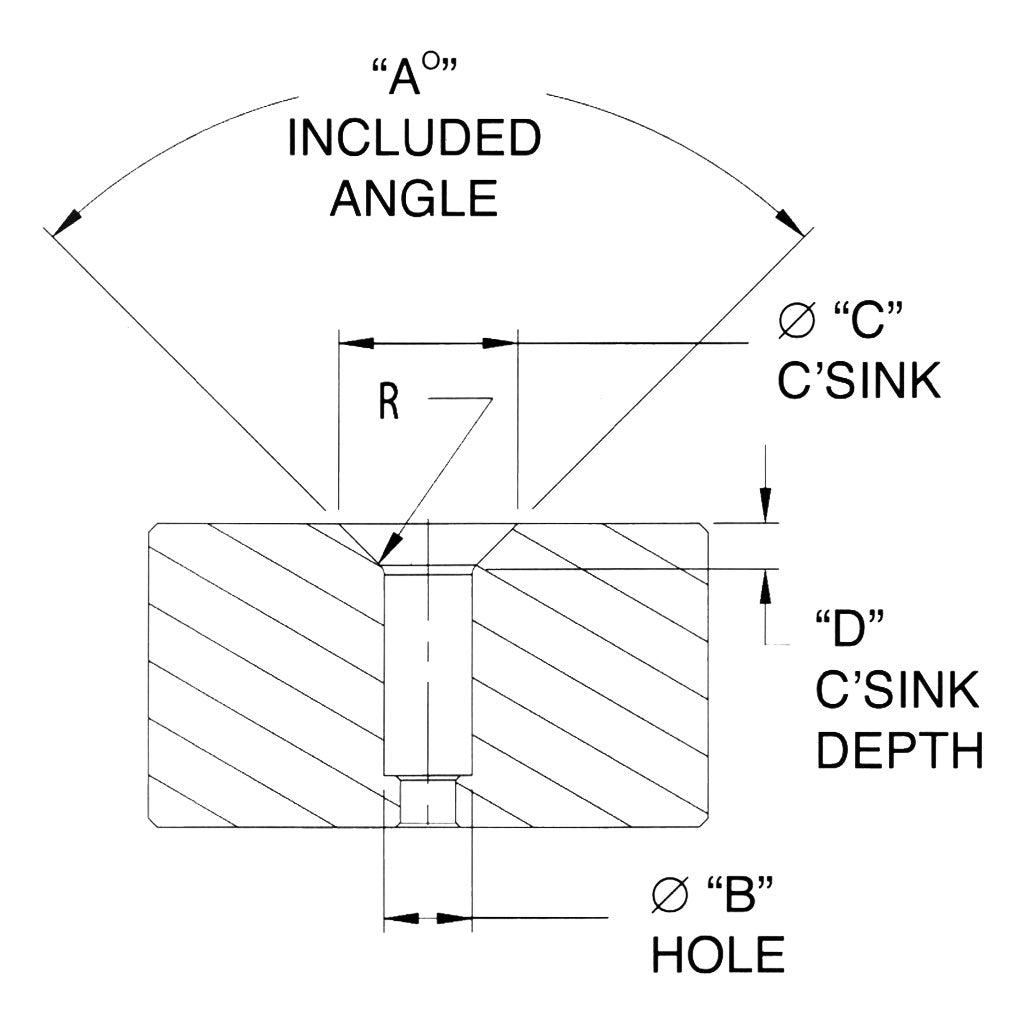

Trulok® gages are built to your exact specifications. Please supply us with the following data needed for the calibration set block that will accompany the gage:

- "A" Countersink included angle:

- "B" Hole diameter through:

- "C" Countersink major diameter:

- "D" Depth of the countersink:

- "R" Transition radius:

- Fastener part number and/or specification:

- Surface curvature:

- Size, thickness, and position of any drilling jig or fixture to measure through: